Background – REP, LLC

Resonant Exploration and Production, LLC (REP) is a

Texas-based, clean-tech company with roots in international deepwater oil and gas exploration, including production operations.

REP’s niche expertise has been addressing the need for hydrate mitigation technology in gathering pipelines. These pipelines in Arctic and deepwater petroleum production sites are susceptible to hydrate formation due to the low temperature and high pressure. REP’s unique focus started in 1969 when its founder began to engineer solutions for hydrate mitigation in deep sea projects.

What are Methane Hydrates?

In the broadest possible terms, a methane hydrate

(AKA ‘gas hydrate’) is a clathrate single compound (methane), nested within the lattice of another (ice).

It is held together due to Vanderwall forces, requiring little energy transfer for dissociation.

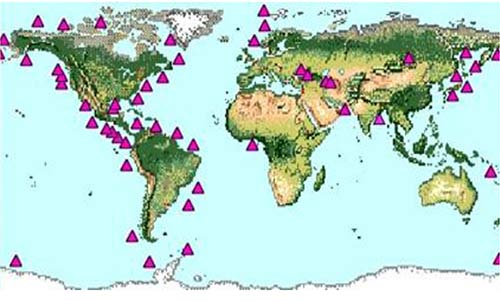

According to the US Geological Survey (USGS), methane hydrates exist in abundant quantities all over the world with an estimated global supply in excess of 700,000 trillion cubic ft. This makes methane hydrates the most abundant energy source in the world.

A USGS representation of known permafrost and sea floor methane hydrate deposits:

RH Well Stimulation

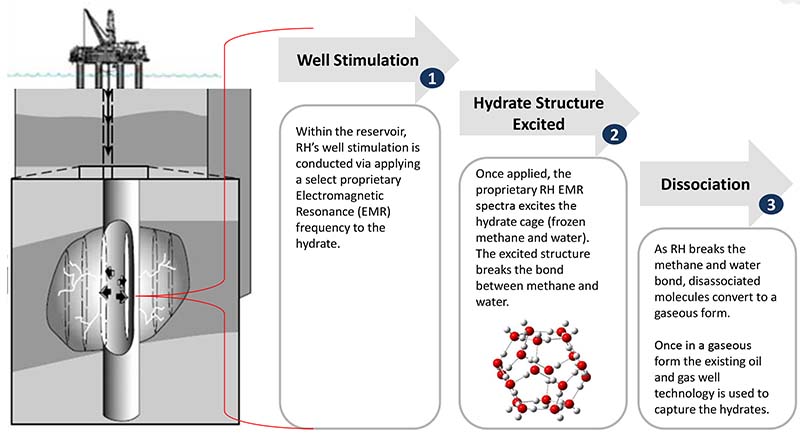

REP’s innovative Resonance Hydrates Methane ( REHM ) well stimulation technology uses a proprietary electromagnetic resonance (EMR) spectra and dissociation process to excite frozen methane hydrates. This process converts frozen hydrates to a gaseous state, enabling safe and cost-effective collection and subsequent commercialization.

Far beyond mere ‘mining’ of methane hydrate deposits, RH well stimulation technology allows precise control over the volatile dissociation of the water-methane bond. The resonant frequencies in the electromagnetic spectrum for breakup of an isolated methane hydrate cage are in the infrared region.

The key REHM spectra and processes have been developed based on research commissioned by REP Technology, LLC with the University of Connecticut and Texas A&M.

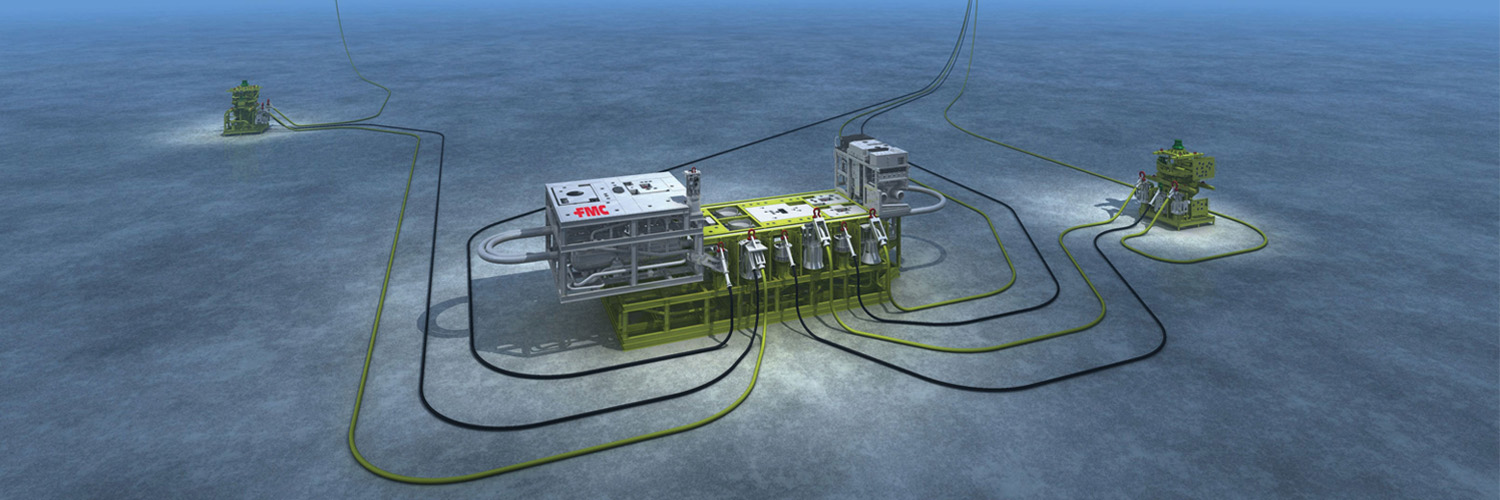

REHM well stimulation technology is added onto existing infrastructure (e.g., offshore oil rigs), making the adoption rate high due to low conversion costs, low risks, and virtually no downtime to convert.

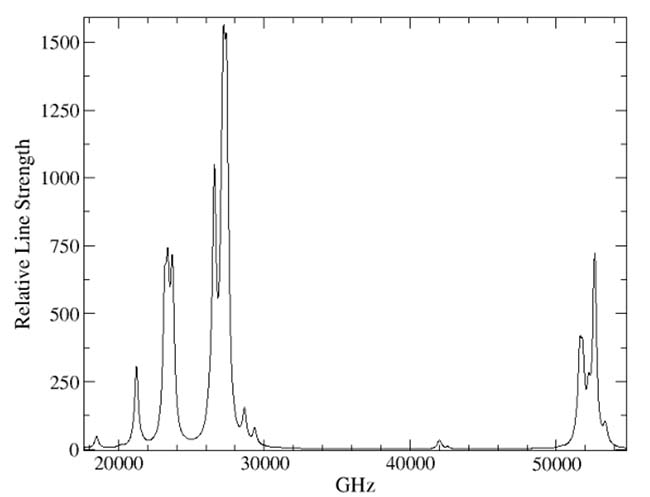

The following graph shows the range of resonance frequencies for dissociation of hydrates:

RH Well Stimulation, How it Works

Current Industry Well Stimulation Competition

Prior efforts by others in the industry have included:

- Pressure Reduction

- Temperature Increase

- Chemicals

Each of these methods has fundamental flaws.

Pressure Reduction:

Reduce reservoir pressure below the hydrate equilibrium pressure (approximately 600 psig) as attempted in recent field tests done by JOGMEC in Japan.

Issue:

JOGMEC has abandoned this approach because the pressure drop required to cause dissociation is far below the pressure of a typical gas reservoir, and the fluid production resulted in difficulties with hydraulics and system operations.

Temperature Increase:

Increase reservoir temperature above hydrate equilibrium temperature.

Issue:

High risk, as it could result in uncontrolled release of methane to the environment.

Chemicals:

Inject chemicals into the gas-hydrate layer to cause dissociation of the hydrate. This method, using CO2 substitution, was demonstrated in a field test in Alaska.

Issue:

Impractical for commercial production due to logistics and the requirement of large quantities of chemicals for substitution.

Consequence:

The abundant methane hydrate deposits are not being used.

REHM’s well stimulation technology will be the world’s next generation fuel supply—surpassing traditional petroleum because of these benefits:

- REHM selectively uses EMR to disassociate methane in a controlled manner.

- REHM well stimulation process enables efficient and selective energy transfer. The energy required for dissociation is small.

- Upon dissociation, methane would be in gaseous phase to enable separation and pipeline transportation.

- REHM plugs into existing oil and gas infrastructure, resulting in easy conversion for petroleum companies, which leads to low conversion costs and a high adoption rate.

Recent Comments